Work Less. Hay More.

Looking for Kuhns MFG?

We’ve rebranded as Norden MFG! Same ownership, same great products, brand new name.

Products to simplify your workload

Browse All ProductsWhat is a

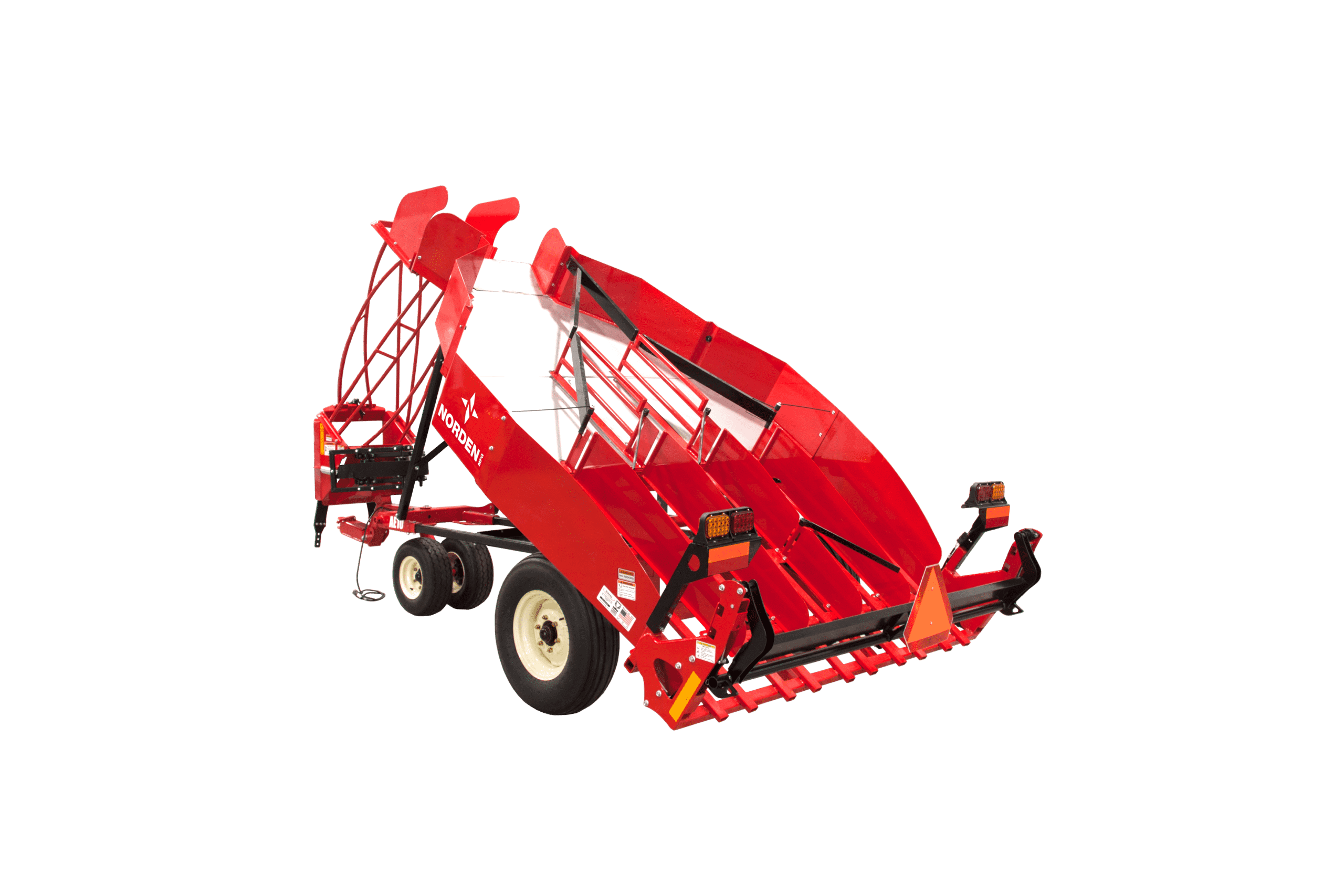

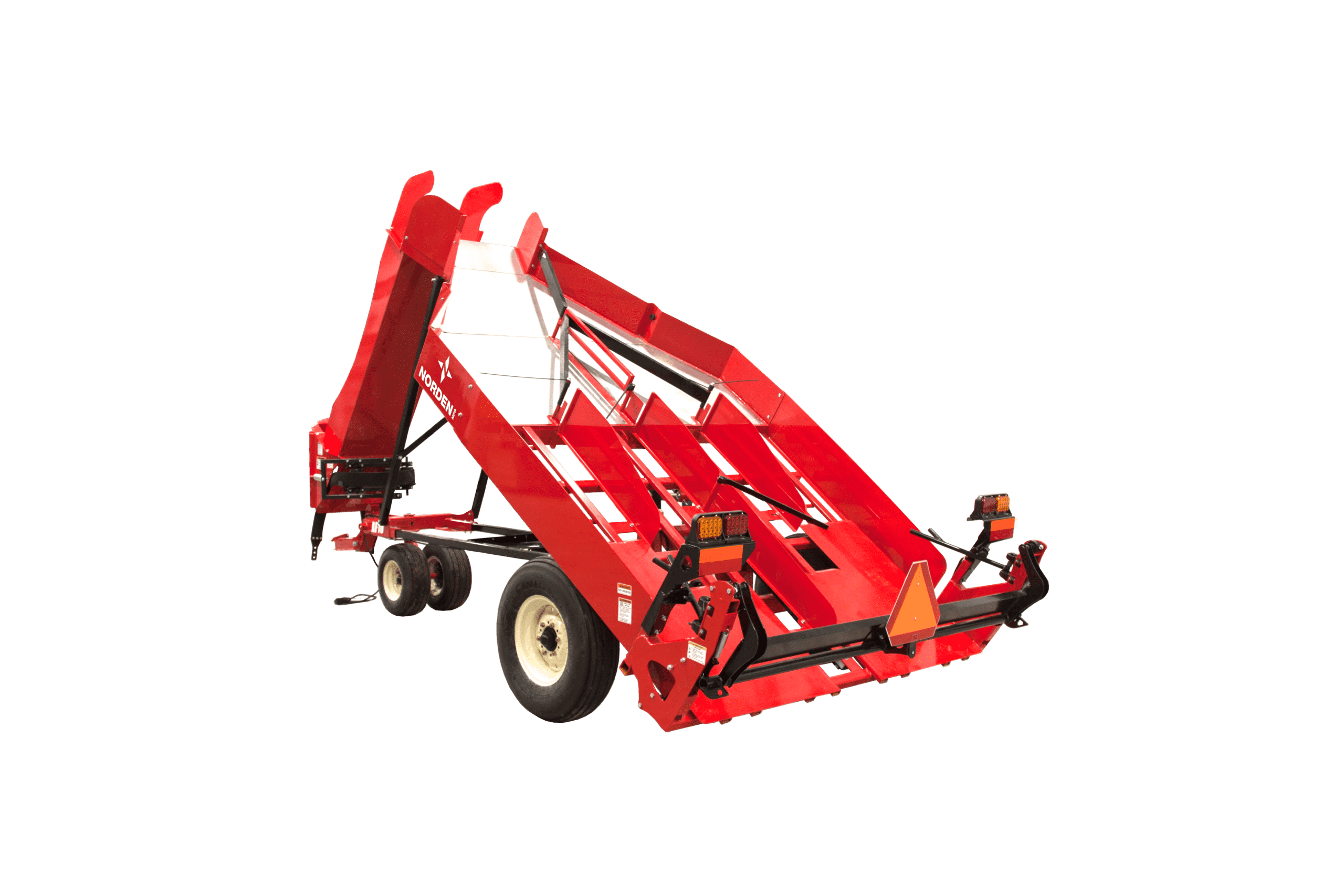

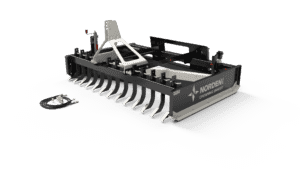

Hay Accumulator

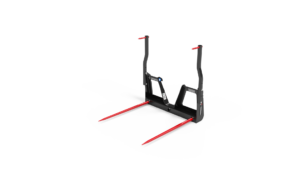

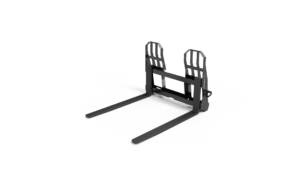

The Norden Mfg Bale Accumulator, or hay accumulator for handling small square bales uses gravity and a simple mechanical system to efficiently arrange bales into a group that then sets the bales together in the field. A Norden Mfg. Grabber or Tie-Grabber mounted on a front-end loader or skid steer picks up the small square hay bales to load them onto a waiting truck, trailer, or wagon for transportation. The groups can then be unloaded into the barn via the grabber without an operator ever needing to touch a bale.

First time buyer?

Let us help you get started